In The Shop

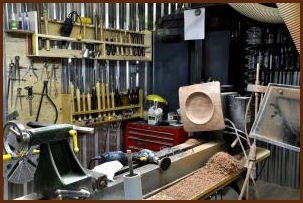

Our wood products are all handcrafted in the shop of Knots to Bowls in Ontario, Canada.

We utilize wood from downed trees In the Kawartha Lakes area, and create wood items for gifts for the home, cottage and office.

Wooden bowls are all turned from local trees that have been damaged by wind and ice storms.

Black Cherry bowl blanks that have been sealed with wax to contain the wood's moisture.

This is how the bowls are prepared before being mounted on the lathe to be turned into a bowl.

This is how the bowls are prepared before being mounted on the lathe to be turned into a bowl.

-

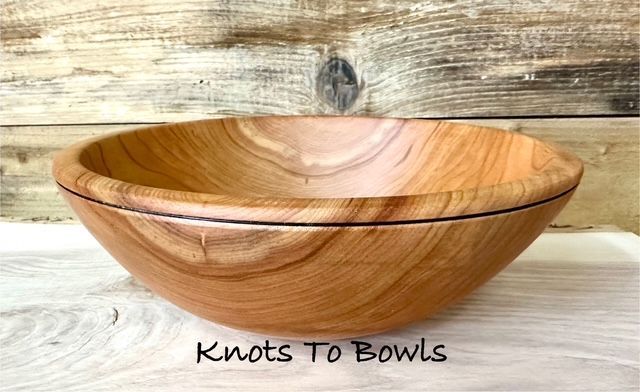

Cherry Wood Bowl with a natural edge is fresh off the lathe.

-

Wood burl has been cut in half in preparation to turn.

-

Large burl on the lathe will eventually become a wood bowl

-

Cherry burl being turned on the lathe.

-

Gorgeous burl bowl with natural edge

-

Bowl is being turned from black cherry.

-

Turning a wood vase on the lathe.

-

Cherry wood bowl is ready to begin the drying process.

The Steps Involved in Crafting a Wooden Bowl From A Log

Here I have the log lifted by the John Deere tractor. I will now decide where to make the cuts on the log.

Cutting sections of the log that will work to make bowls. Scrap is used to heat the workshop.

I have now taken one of the cut logs and cut it in half and removed the sharp corners.

At this stage the new bowl to be is centered on the face plate of the lathe ready to be turned.

The bowl has been mounted on the lathe and the bottom is beginning to take shape.

I have the wood in position to start hollowing out the inside. It's still not ready to add the popcorn, but we are getting closer.

I'm seeing some nice grain now as I continue to hollow out this cherry wood bowl.

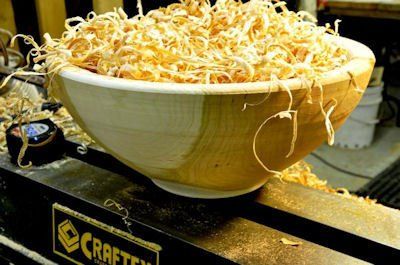

The new salad bowl now has a good shape and is completely rough turned. It is left extra thick because it will begin to change shape a little as it is drying.

Once rough turned the bowl is placed in a large cardboard box along with the damp shavings in order to allow the wood to dry slowly. It is then stored in a cool area.

It will remain covered in the box for 4 months then it is removed from the box and it will air dry on a drying rack for another 6 to 8 months. After close to 1 year of drying the bowl will be mounted again on the lathe and turned and cut to its final shape and size.

It will remain covered in the box for 4 months then it is removed from the box and it will air dry on a drying rack for another 6 to 8 months. After close to 1 year of drying the bowl will be mounted again on the lathe and turned and cut to its final shape and size.